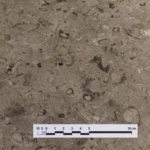

The beauty of the characteristic floral appearance is given to the stone by sections of fossils, which are especially well preserved here. The different gray shades of the stone enable different combinations, both within the Lipica Fiorito stone itself, as well as with other types of natural stones and materials.

It is suitable for both indoor and outdoor use.

Pick-up Location

Partizanska cesta 73 A, 6210 Sežana

Mon–Fri: 8:00 am–4:00 pm

Methods of treatment

We treat the surface of our materials in different ways; polished, honed, bush-hammered, rough bush-hammered, fine bush-hammered, micro-bush hammered, scored, flamed and chiselled. Brushed treatment can be add to all rough treatments, which makes the material easier to clean and maintain, so rough treatments can also be suitable for indoor use if brushed hard.

Treatments description

Flamed and brushed

After the thermal process of flaming, the surface is brushed with special abrasive brushes, which remove the roughness.

Scored

This finish is characterized by a succession of flanked grooves carried out using diamond discs or a wide range of variable–profile tools. This finish can be obtained on materials that are at least 3 cm thick.

Bush hammered

Is a typical Karst finish, it is used to give a rustic appearance, hide imperfections and color variations in addition to making it slip – proof. The bush-hammering effect is obtained using a diamond – nosed hammer, the bush – hammer and the resulting texture can vary from rough to fine–grained and encompass all other textures in between. This finish can be applied to materials that are at least 3 cm thick.

Rough bush hammered

Is a typical Karst finish, it is used to give a rustic appearance, hide imperfections and color variations in addition to making it slip – proof. The bush-hammering effect is obtained using a diamond – nosed hammer, the bush – hammer and the resulting texture can vary from rough to fine–grained and encompass all other textures in between. This finish can be applied to materials that are at least 4 cm thick.

Flamed

Is a thermal process obtained using oxygen and gas. The finish is created by applying an extremely hot flame to the surface, which undergoes to thermal shock. This process makes the surface coarse and in relief. This finish can be applied to materials that are at least 3 cm thick.

Fine bush hammered

Is a typical Karst finish, it is used to give a rustic appearance, hide imperfections and color variations in addition to making it slip – proof. The bush-hammering effect is obtained using a diamond – nosed hammer, the bush – hammer and the resulting texture can vary from rough to fine–grained and encompass all other textures in between. This finish can be applied to materials that are at least 2 cm thick.

Micro bush hammered

Is a finish used to give a rustic appearance, hide imperfections and colour variations in addition to making it slip – proof. The bush-hammering effect is obtained using a diamond – nosed hammer, the bush – hammer and the resulting texture can vary from rough to fine–grained and encompass all other textures in between. This finish can be applied to materials that are at least 2 cm thick.

Hand chiselled

Is a typical Karst finish, it is obtained by striking the stone surface by hand, using a pointed tool and a mallet. The final result is an extremely evident texture that showcases contrasting colors. This finish can be applied to materials that are at least 4 cm thick.

Come around.

Write to us.

Skilled salespeople and architects will make sure that your wishes and dreams become reality. If you need an advice or an offer, you can meet with us at the company's headquarters or fill out the online form.